CNC MILLING, moulding details and prototypes

[ Master moulds - temporary moulds - final moulds ]

List of main activities:

- Smoothing treatments with abrasive instruments.

- Painting treatments (funds, primers, water based paints)

- Treatments with waxing products

- Layering with epoxy resin and vinyl ester resin

- Transferring structures on wood or iron moulds

- Moulding and polishing

- Production of moulds from prototypes and master models.

- Layering of pre-series particulars

- Are you interested?

- Contact us to: tech@caselani.com

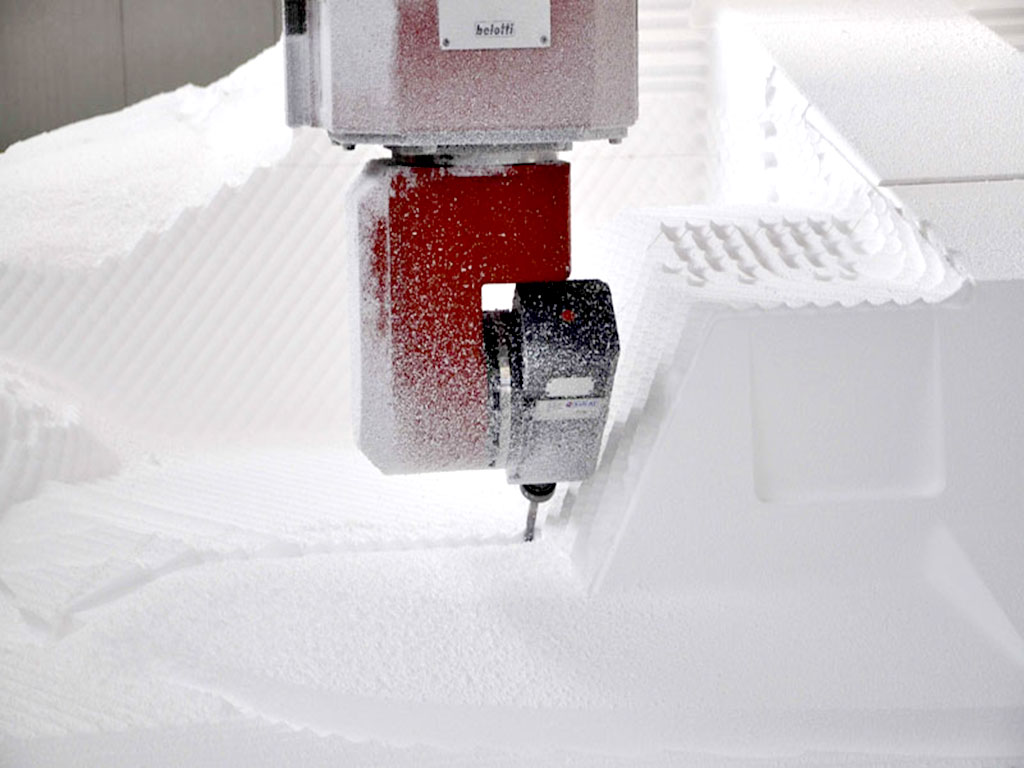

CNC Milling machine

[ Useful dimensions of the milling machine : 12 m x 6 m x 2 m ]

for the realization of prototypes, models and pre moulds.

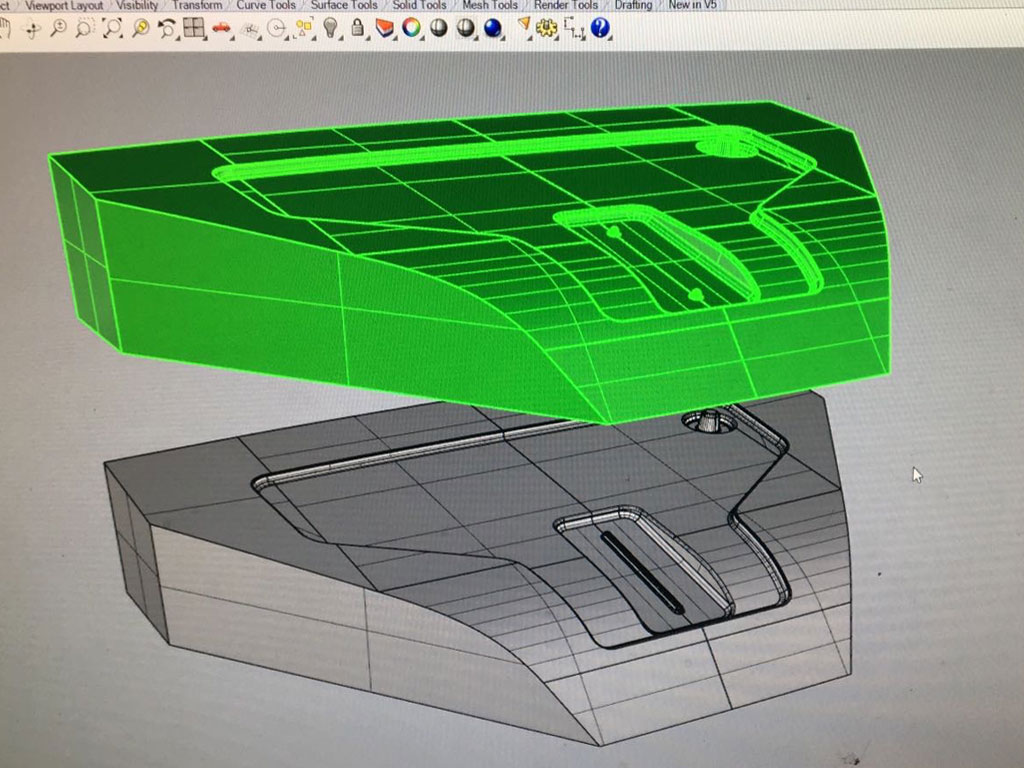

This enables us to complete the whole production process in the nautical sector (from the 3d design to the realization of the finished product).

TYPES OF MATERIAL WE WORK ON: - polystyrene

- expanded polyurethane

- mdf

PLANNING OFFICE CAD CAM: consultation, planning, realization of style models and prototype models.

PROCESSING TECHNIQUES: basic milling - double milling with finishing plaster - fiberglass mould - sanding of the prototype or pre mould.

SECTORS:

- Nautical Sector - Fiberglass Processing – Events and Communications - Foundries - Prototyping Studio - Architecture Studio - Planning Studio - Product Design – Display builder - Statues - Poster 3D - Carousels - Swimming Pools - Scenic Design